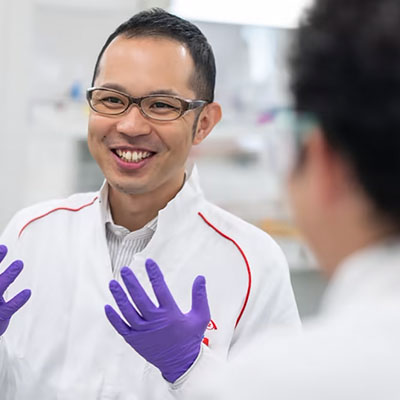

Employee Spotlight: Kenneth Brown

Kenneth's Story

As we pursue our purpose to create better health for people and a brighter future for the world, we know that every member of our team has their own journey. Learn more about Kenneth and his path at Takeda.

Kenneth, tell us about a bit about your job at Takeda?

I’m a Senior Manufacturing Technician in the Albumin department in our Covington facility. In this team, we make Flexbumin which is a plasma-derived therapy. This therapy has a wide range of uses for patients with burns, liver conditions, trauma, cardiopulmonary issues, and more.

In the Albumin team, we take the yellow-colored, albumin-rich paste we receive from the Fractionation department and further process it with a filtration system.

Our team takes the paste through four different steps:

- Step one is to suspend and reconstitute the paste in water. We then add alcohol, wait for an aging time and run the [now-liquid] product through a depth filter/guard filter and to remove any protein denatured precipitates.

- Step two uses an ultrafiltration/diafiltration vessel to remove alcohol and ions and concentrate at the right level with the help of special membranes.

- In step three, the albumin is formulated, heated to a certain temperature, and then cooled.

- Once cooled down, the albumin is transferred to bulk bio process containers and shipped to Takeda’s facility in Round Lake, Illinois, where it will be filled into flexible plastic bags.

You were recently promoted – congratulations! Why do you feel you were selected for a promotion?

I feel I was selected for a promotion because I took the initiative to learn every area in the Albumin department. I cross-trained in different areas of the team which made me a valuable resource because I then had the ability to step in to cover shifts in emergency situations or for team members who were on vacation.

I knew that I wanted to move up in my career, so I also took advantage of training opportunities and earned my certifications as both a Subject Matter Expert (SME) and Qualified Trainer (QT).

I also feel that my sense of urgency in completing tasks assigned to me by my [team] lead or supervisor was a factor in my success.

What attracted you to Takeda and what do you like most about working here?

I became interested in Takeda when I saw an advertisement for the Manufacturing Skills Assessment. Unfortunately, I didn’t do as well as I would have liked on my first attempt. I waited one year, retook the assessment, and performed well enough to be moved forward to the three-round interview process. At the conclusion of the process, I was hired on as an Albumin Manufacturing Technician. That was in the summer of 2018.

As a native of Detroit, I watched my father work at the Ford Motor Company for over 30 years. I observed how innovative Ford was and how they didn’t necessarily do things the way everyone else in the automotive industry did. This made them stand out to me in a good way.

I see a similar approach taken at Takeda. Our job isn’t one where we just clock in and clock out. We come together as a team, find new ways to solve problems, and get job done right – each and every time.

Tell us a little bit about your background and your interests outside of work.

As I said above, I was born and raised in the Motor City: Detroit, Michigan.

After high school, I earned an Associate’s Degree in Network Administration and started working.

Several years ago, my father became ill. My family had since relocated to Georgia and I decided to move down there, too, spend more time with him.

As far as hobbies go, one of my favorite things to do is go over to my mom’s house, and barbecue and smoke meat. I’m also an avid fan of anime."

Jobs for you

- Manufacturing Associate Lexington, Massachusetts Category: Manufacturing/Production

- Manufacturing Lead Associate - Nights Lexington, Massachusetts Category: Manufacturing/Production

- Project & Process Scientist for Development Projects and Technology Transfer (m/w/d) Oranienburg, Germany Category: Manufacturing Sciences

- Supply Chain Business Analyst (w/m/d) Oranienburg, Germany Category: Supply Chain